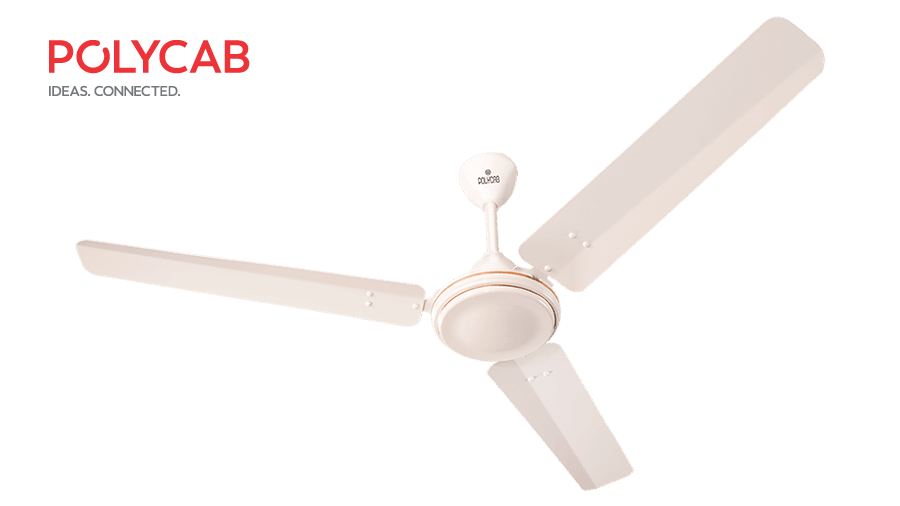

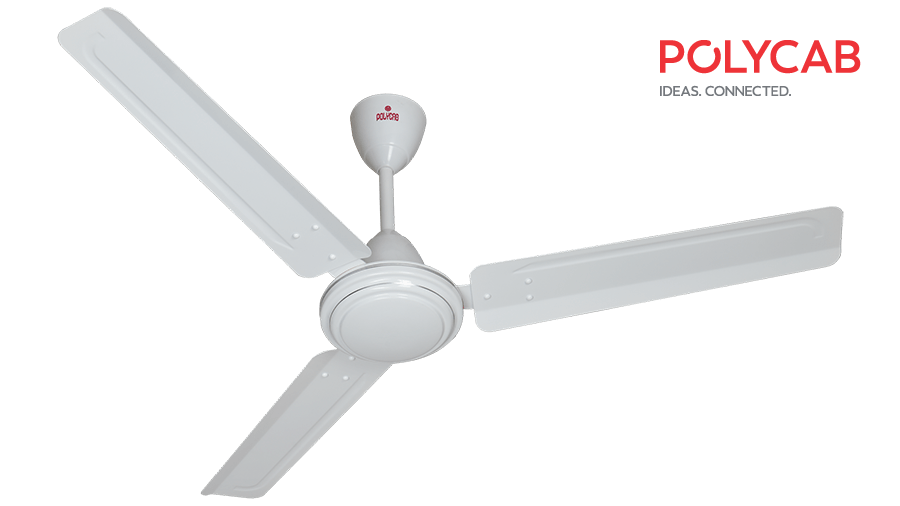

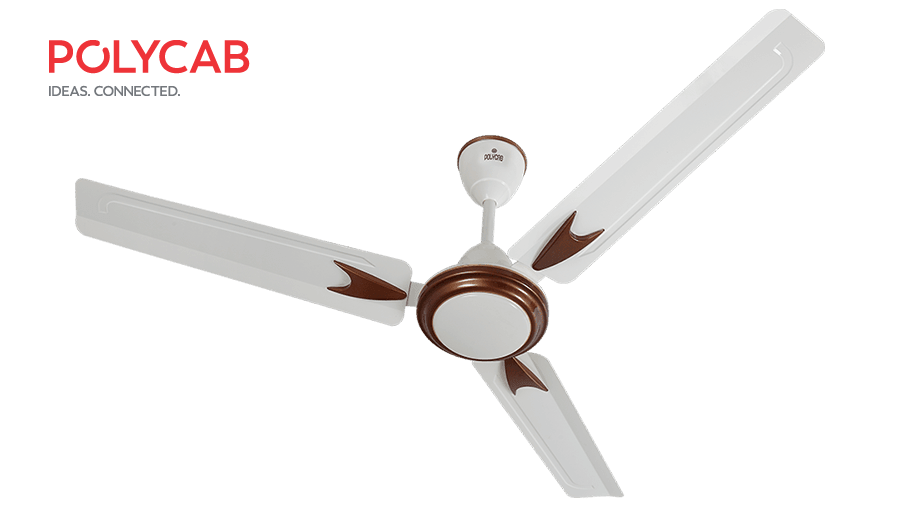

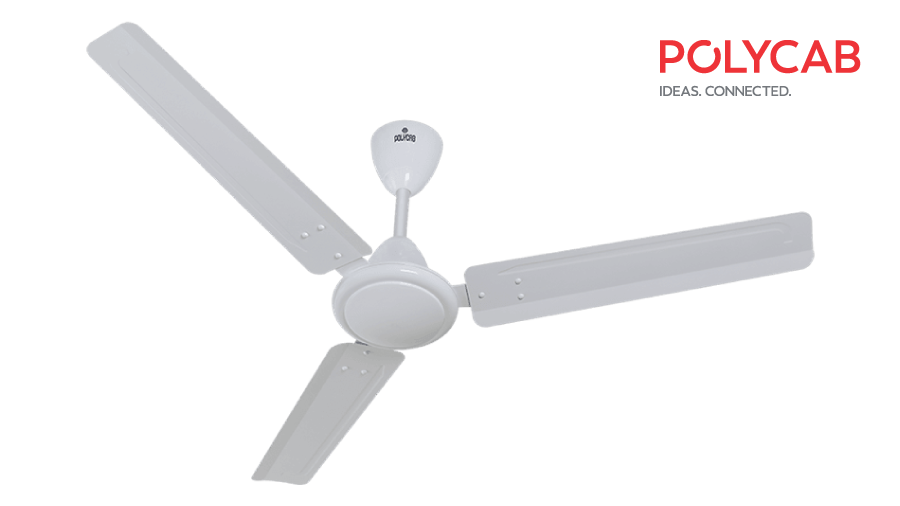

AMAZE HS

White

Also available :

- Bianco

- Matt Brown

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 | 75 | 400 | 235 |

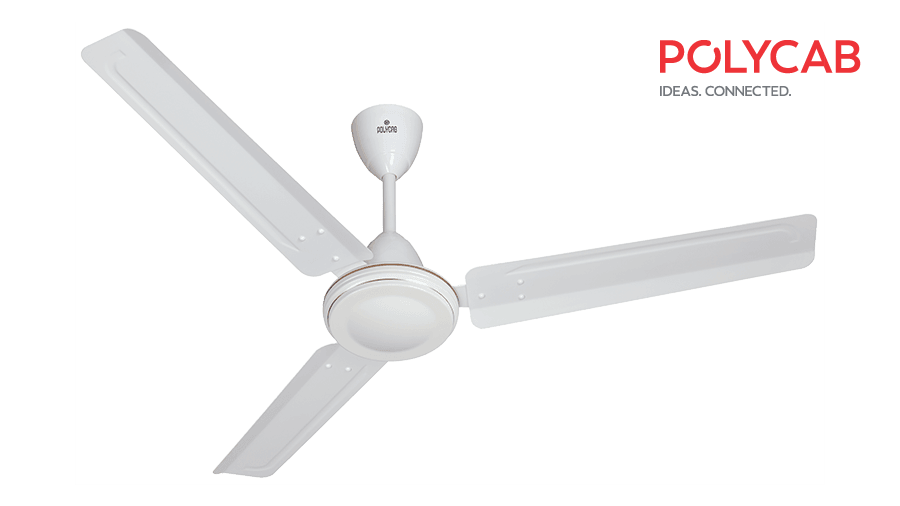

AMAZE DLX

White

Also available :

- Matt Brown

- Bianco

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1400 / 1200 / 900 / 600 | 75 / 75 / 70 / 75 | 290 / 400 / 440 / 800 | 250 / 235 / 150 / 120 |

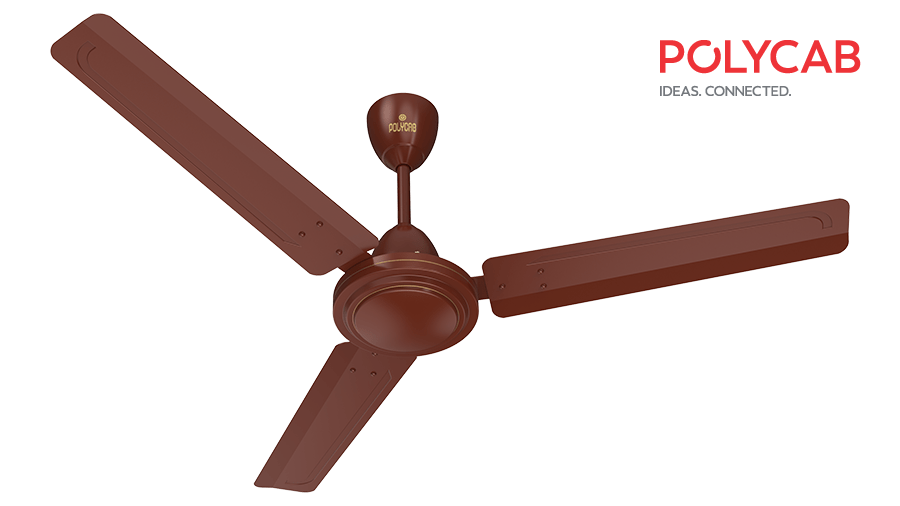

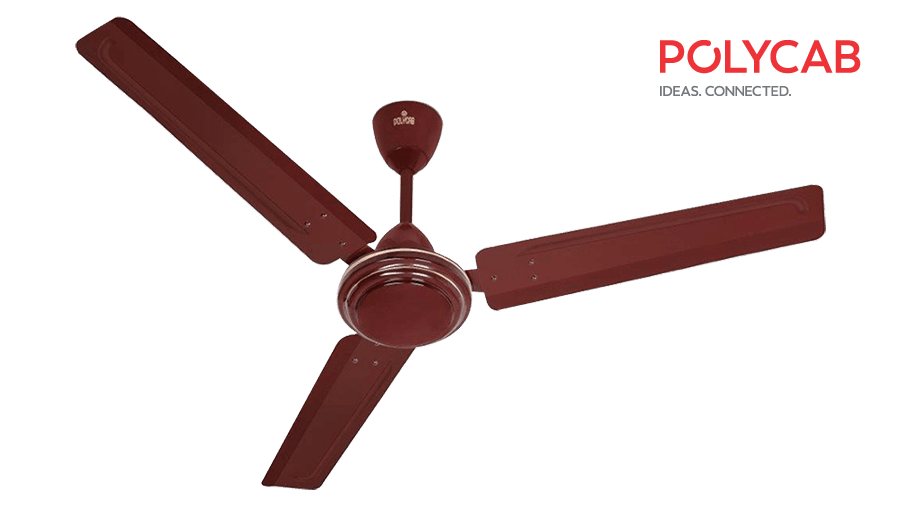

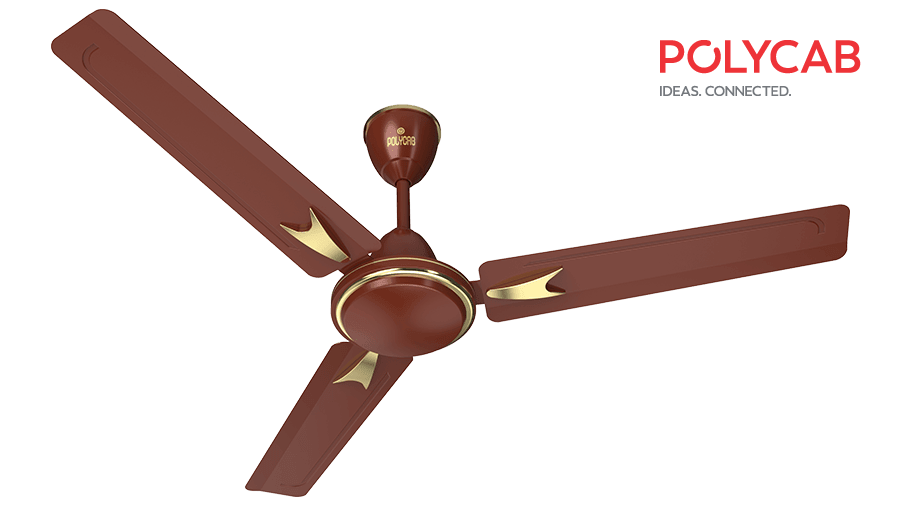

GLORY

Luster Brown

Also available :

- White

- Bianco

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1400 / 1200 / 900 | 75 / 75 / 90 | 290 / 400 / 650 | 250 / 225 / 160 |

JUNO

White

Also available :

- Luster Brown

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 | 75 | 400 | 225 |

ZOOMER

Luster Brown

Also available :

- Bianco

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1400 / 1200 / 1050 / 900 / 600 | 75 / 75 / 75 / 70 / 75 | 290 / 400 / 400 / 440 / 800 | 250 / 225 / 160 / 150 / 120 |

ZOOMER DLX

Luster Brown

Also available :

- Bianco

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1400 / 1200 / 1050 / 900 / 600 | 75 / 75 / 75 / 70 / 75 | 290 / 400 / 400 / 440 / 800 | 250 / 225 / 160 / 150 / 120 |

SYLPHY

Luster Brown

Also available :

- Bianco

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 / 1050 / 900 | 75 / 75 / 70 | 400 / 400 / 440 | 225 / 160 / 150 |

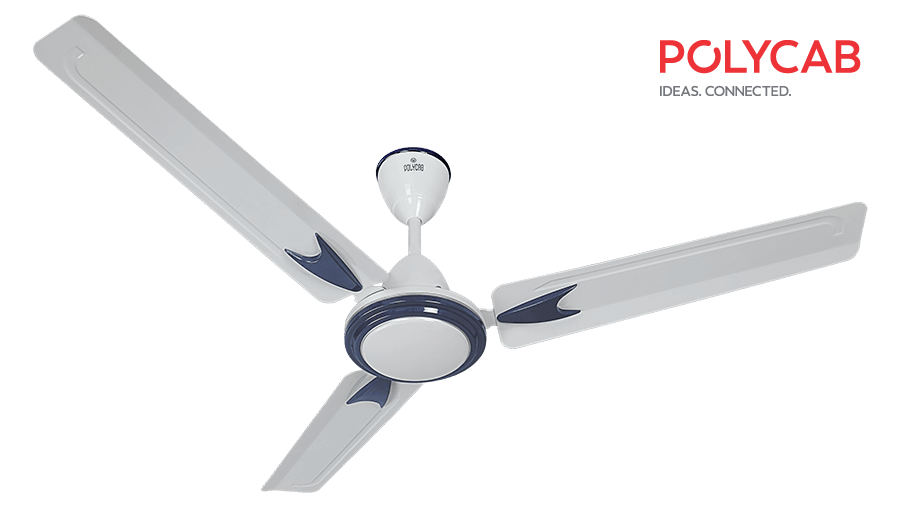

SYLPHY DLX

Bianco Pearl Woodland

Also available :

- Luster Brown HD Beige

- White Pearl Blue

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 / 1050 / 900 | 75 / 75 / 70 | 400 / 400 / 440 | 225 / 160 / 150 |

ANNULAR

White

Also available :

- Luster Brown

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 / 1050 / 900 | 75 / 75 / 70 | 400 / 400 / 440 | 225 / 160 / 150 |

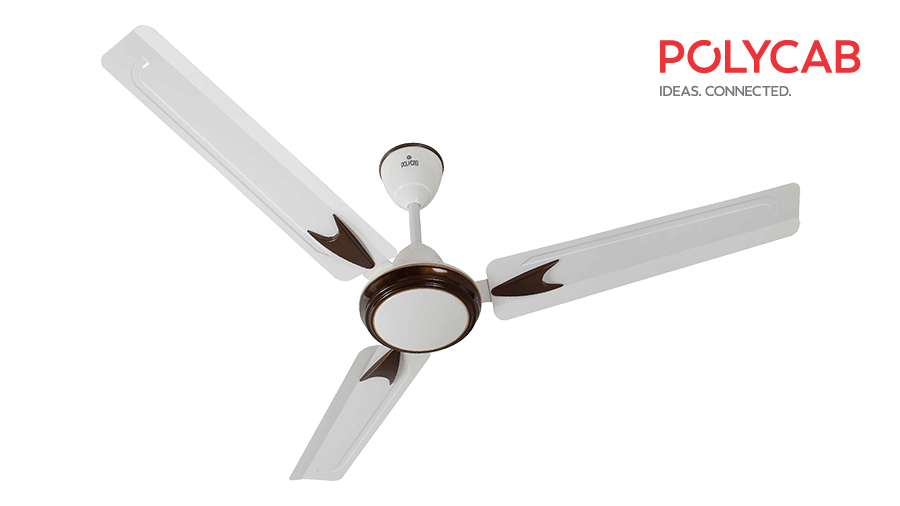

ANNULAR DLX

Bianco Honey Gold

Also available :

- Bianco

- Wine Red

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 / 1050 / 900 | 75 / 75 / 70 | 400 / 400 / 440 | 225 / 160 / 150 |

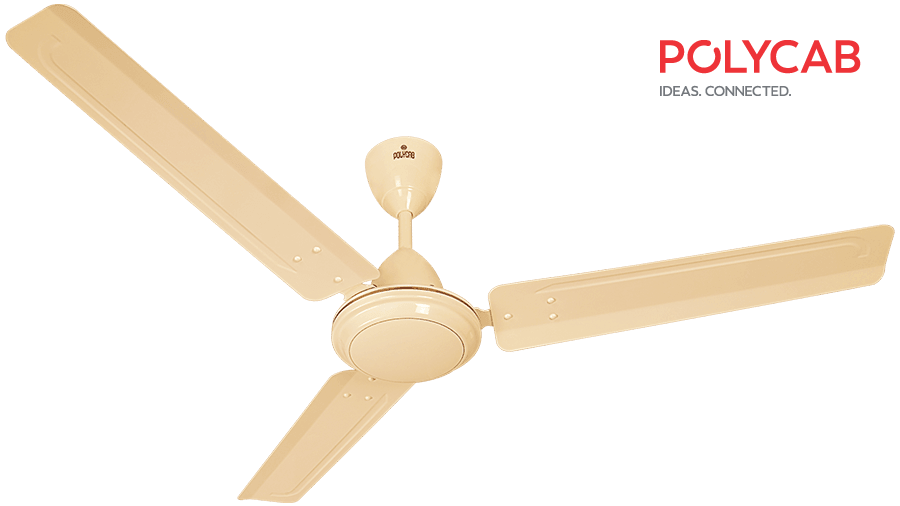

VIVA

Bianco

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 / 1050 / 900 | 75 / 75 / 70 | 400 / 400 / 440 | 225 / 160 / 150 |

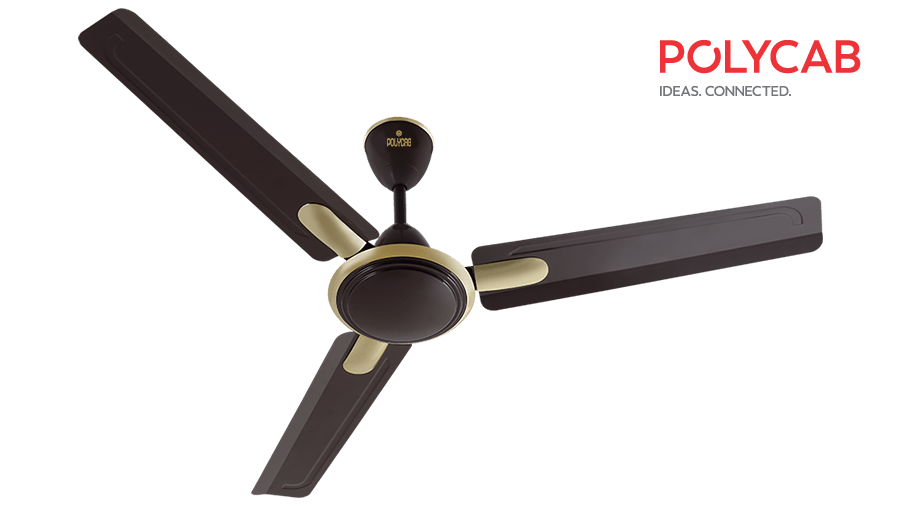

VIVA DLX

Luster Brown

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 / 1050 / 900 | 75 / 75 / 70 | 400 / 400 / 440 | 225 / 160 / 150 |

ETERNA

Brown

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 | 75 | 400 | 225 |

REVIVO

White

Technical Specifications

| Sweep (MM) | Power Input(w) | Speed (RPM) | Air Delivery (CMM) |

|---|---|---|---|

| 1200 | 75 | 350 | 210 |

An advanced nano coating which protects Polycab fans from dust, rust and microbial germs.

A high speed ceiling fan is a fan that delivers excellent air circulation throughout the room, owing to its high-performance motor.

Polycab fans use double ball bearing that support the motor and fan shaft at two locations. Such fans have reduced friction and perform consistently in any orientation.

A uniquely engineered motor that generates low body heat even after running for a few hours. This greatly enhances the motor’s efficiency.

A tried and tested process that involves eliminating material impurities followed by removal of defects from a painted surface. It offers superior finish and long lasting protection.

Load loss can be reduced and electrical energy efficiency can be improved by increasing the cross section of copper coils. Hence Polycab’s high efficiency motor use higher amount of copper in the winding.

The totally enclosed and ruggedly built heavy duty motor ensures high performance and delivers maximum output at lower operating cost.

Abbreviation for Maximum Performance Minimum Voltage. It’s a high-performing electric motor that operates at maximum efficiency yet consumes minimum voltage.

With larger and wider fan blades, Polycab Fans range give you the highest air delivery and wide air throw that cool every corner of the room.

The highest grade of pure copper, also known as electrolytic grade copper, is used for motor winding in Polycab fans. It is thermostatically balanced, maximises electrical conductivity and is highly efficient.

The blades used in Polycab fans are engineering masterpieces that use intelligent design to push maximum air delivery downwards. The asymmetric alignment of the blades coupled with higher blade width also ensures better air delivery.

The aerodynamically designed blades reduce the drag from air and maximize air delivery.

Well-defined controls have been put in place to standardize production and quality inspection. Trained personnel conduct regular audits of every material and process from entry to exit stage thus ensuring consistent product quality every single time.

Polycab ceiling fans come in a variety of finishes and colors. You can select a color which suits your application and matches your room perfectly. Listed below are the various finishes to choose from: Pearl | Metallica | Electroplated | Luster | Antique Copper

A highly specialized coating that prevents rusting and provides robust protection against corrosion.